DAF T244 Technical Information

Nominal values (from the handbook) are provided in black text.

Real-life values measured or determined by me are in red text.

Real-life values measured or determined by me are in red text.

Powertrain |

Performance & Efficiency |

|

Engine model: Cummins 6BT

Enginer Displacement: 5.9 Litres Power: 107kW (145 bhp) @ 2600 rpm Gearbox: 5 speed syncromeshed Transfer case: Permanent 4wd, 2 ratio Drive Belt: 8PK 1460 (8 ribs, 1470mm length) |

Max speed: 88kmph (54.7 mph)

At 48kmph (30mph)

|

Wheels and TyresTyre size: 12.00 R20 18 ply

Standard Tyre: Goodyear G388 (with inner tube) Wheel and Tyre assembly weight: 140kg Tyre Pressures (from experience) Tar (good) - 90-110 psi (6.2-7.6 bar) Tar (Africa) - 80 psi (5.5 bar) Gravel / potholes - 60 psi (4.3 bar) Sand recovery - 40 psi (2.8 bar) I never let my speed (in km/h) exceed my tyre pressure (in psi). I.e. I don't exceed 60km/h with tyres at 60 psi to avoid overheating. |

WeightStandard weight unladen (flatbed variant): 5980 kg

Our build weight: 9000 kg fully loaded. |

Filters

Below is a list of compatible filters by brand and part number, all will fit. The list is not exhaustive but should help you source a part.

|

Air

Donaldson P181064

Cummins 196676 Cummins 196677 Cummins 204623 GUD ADG537 |

Oil

Cummins 3932217

GUD Z345 |

Fuel

Cummins 3843760

Donaldson P550248 Fleetguard FS1251 Baldwin BF1226 GUD Z287 |

Dryer

Wabco 4324102227

GUD Z316 |

Ex MOD Manuals (released under FOI requests)

All the Leyland DAF T244 manuals zipped up into two archives. (You will need WinZip, WinRar, or similar to extract the PDFs).

|

| ||||||||||||

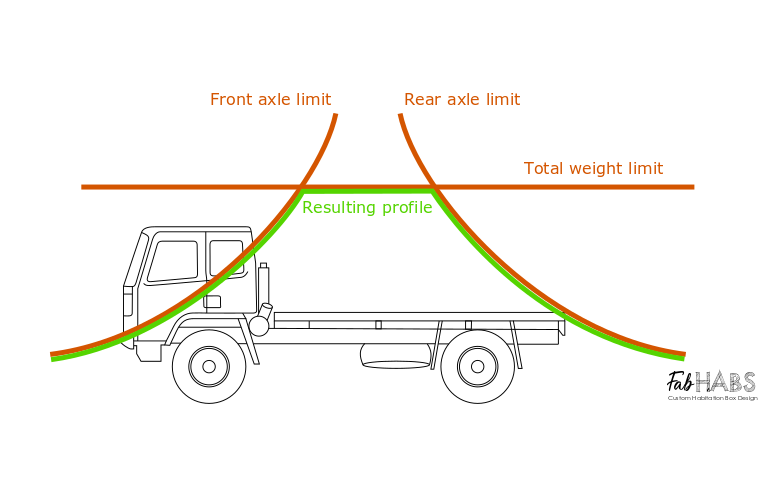

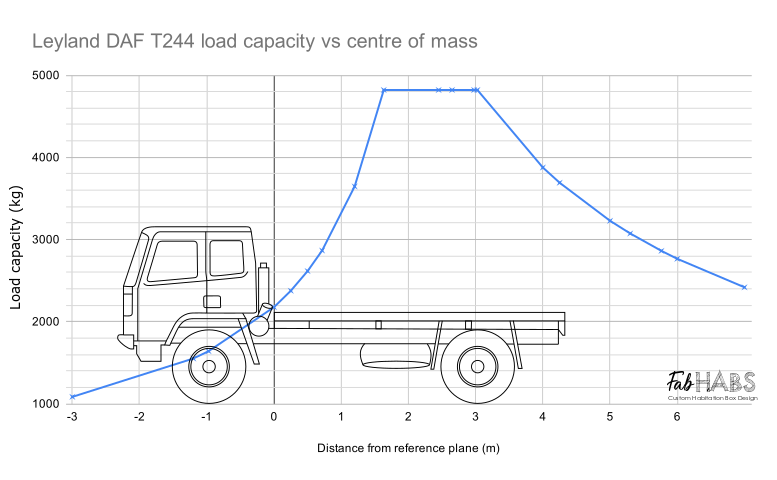

Leyland DAF T244 weight distribution and axle limits

Where the centre of mass of any additional loads greatly determines how much you can carry. Don't think you can put 4.5t on the back just anywhere. Builders will need to ensure they are well under the front axle, rear axle, and total vehicle limits.

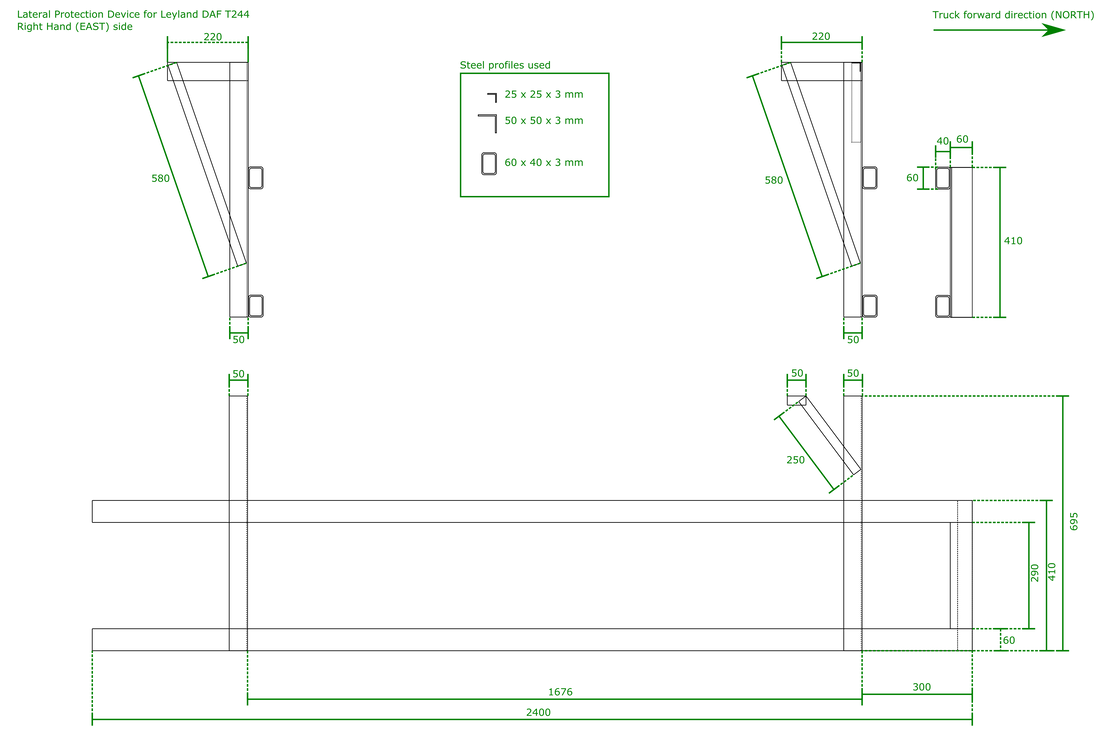

Lateral Protection Device (Side Guards)

You need to have side guards present to get a UK MOT for the Leyland DAF T244 unless you are registered as a "motor caravan". The design below is one I used. It's made of steel stock and bolts directly to the load bed (you will need to drill suitable holes. I recommend M8 bolts and Nyloc nuts. This design is heavier than standard LPD's which are usually aluminium but it survived our trip through Africa including us using them as steps to climb in and out so it's at least tried and tested.

Advice to T244 owners travelling in Africa

- Carry oil, fuel, and air filters with you wherever you go. At least one of each.

- Carry oil and gearbox fluid (5L each) wherever you go.

- Invest in a grease gun and grease cartridges. These can be hard/impossible to find in the bush. The propshaft joints are supposed to be greased after every 700 miles or so, more often on rough terrain.

- Check your transfer case (low/hi range gearbox) engages before setting off. I found the best way to engage it is on a downhill stretch of road, roll the vehicle at walking speed and double de-clutch. i.e. Start in HI 2, depress clutch, move to neutral, release clutch, depress clutch again, switch to low range (still rolling at walking speed), release clutch, depress clutch, engage LO 3, release clutch. This procedure requires forward planning and you may find that if you get stuck in mud/sand in hi range, you are not able to engage low range. If you suspect off-road terrain will be encountered, for example you are entering a national park, then do this before., You can still drive 50kmph in low range which is above the speed limit in many parks.

- Test your diff-lock before you go. Pressing the pneumatic button in the cab and driving forward for a bit will engage it but disengaging it can be harder. To disengage it, you need to reverse for up to 20m. If it gets stuck try going forwards and reversing a few times. If yours is stiff and won't release you'll need to release the tension from the rear wheels. Either jack up one wheel, or take off the propshaft. Removing the propshaft under tension is dangerous (easy way to lose your teeth) so try to avoid this.

- Check and clean the fuel sediment trap regularly. The standard steel tanks are prone to rust and the design of the tank means that sediment is sucked in when going uphill.

- The standard headlights are not very useful. They are OK if you are alone in the bush (you can drive by them) but on a road with other cars or at high speed they are not great. Avoid driving at night or get an LED bar.

- The cab is very noisy as standard. Invest in some blankets or carpet inside the cab. This will help a great deal.

- The air lines have push-fit connectors with rubber o-rings inside that are prone to perishing and slowly leaking air. Carry a box of o-rings with you. 1/4 inch or 6mm ones especially, they both work but they are hard/impossible to find.

- Fit a quick-connect pneumatic adaptor to the air valve (near the spare tyre) and invest in a crimped rubber hose about 6m long and a truck tyre regulator. This way you can inflate/deflate your tyres yourself using the engine compressor.

- Drive slowly. 45mph is probably the optimal speed for these truck stock. 56mph is too fast and your drivetrain will suffer.