What is the 'killer dowel pin'?

As far as I know, all standard DAF T244's are equipped with a Cummins 6BT 12v engine.

By most accounts this is a great engine, especially for overlanding. It has no electronics, plenty of available spares, and well documented maintenance. In the DAF T244, once the cab is lifted up, there is ample access to the engine for maintenance.

The 'achilles heel' of this engine is the Killer Dowel Pin. A metal dowel pin which wiggles loose and can fall into the timing gears, perhaps totaling the engine. Fortunately this failure mode is easy to prevent.

By most accounts this is a great engine, especially for overlanding. It has no electronics, plenty of available spares, and well documented maintenance. In the DAF T244, once the cab is lifted up, there is ample access to the engine for maintenance.

The 'achilles heel' of this engine is the Killer Dowel Pin. A metal dowel pin which wiggles loose and can fall into the timing gears, perhaps totaling the engine. Fortunately this failure mode is easy to prevent.

Preventative action

To access the KDP, the timing cover on the front of the engine must be removed. This is a fair bit of work if you're not experienced but it is fairly simple and been described well here: TST’s Dowel Pin Fix Kit for Cummins “B” Engines

Don't forget that you'll need a new crankshaft seal and timing cover gasket! You might as well put a new auxiliary belt on while you're there.

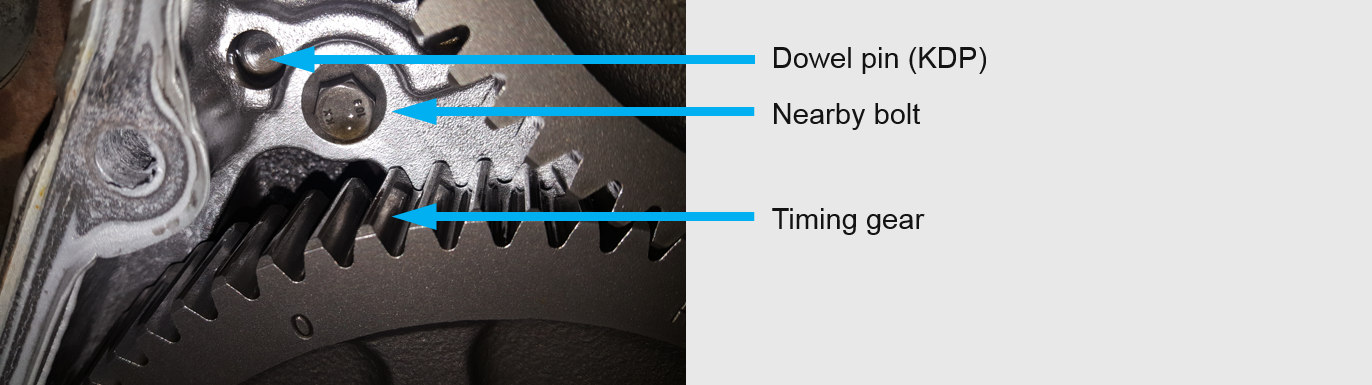

Once you've got the front of the engine off, you'll be able to see the elements in the above picture.

Most, if not all, KDP fixes involve adding a custom washer under the nearby bolt that will hold the dowel pin in. There are no significant loads on this part so all you have to worry about is vibration, heat, and oil.

There are custom washers you can purchase (~£30 in the UK) but I took advice from this thread and used a piece of metal wire from a coat hanger.

Most, if not all, KDP fixes involve adding a custom washer under the nearby bolt that will hold the dowel pin in. There are no significant loads on this part so all you have to worry about is vibration, heat, and oil.

There are custom washers you can purchase (~£30 in the UK) but I took advice from this thread and used a piece of metal wire from a coat hanger.

It almost goes without saying that you choose this solution at your own risk, but just in case, I've said it.

Update (Oct 2019)

This fix survived 20,000 miles of rough driving and corrugations. I think it's safe to say this fix is fairly stable.

This fix survived 20,000 miles of rough driving and corrugations. I think it's safe to say this fix is fairly stable.