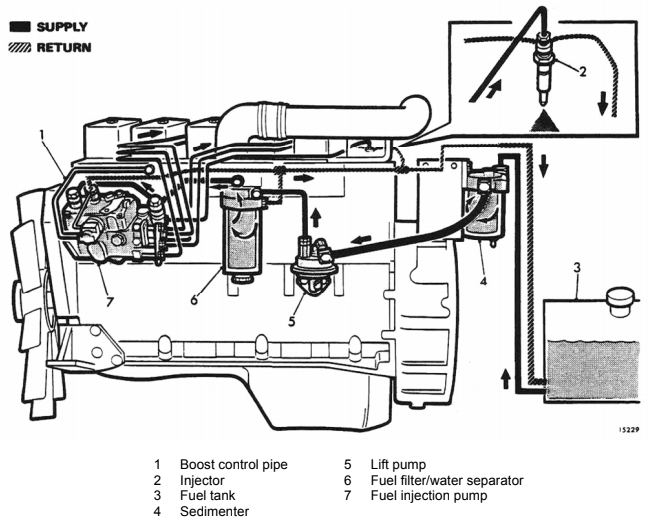

Stock Fuel System

The DAF T244 is equipped with a 135 litre steel tank (3 in diagram below) which after 10+ years is bound to rust. A fuel line runs from the tank to the fuel sedimenter which allows particles (like rust) to drop to the bottom. There are reports that some buyers have found the sedimenter (4) bypassed by the MOD, later we'll see why this is inadvisable. Another fuel line runs from the sedimenter (4) to the lift pump (5). All the lines up to the lift pump operate under suction and if a leak develops in them (at the push-fit connections) diesel will not come out, but air will be sucked into the fuel system, impacting performance and possibly stranding the vehicle. From the lift-pump (5) a steel line runs to the fuel filter (6) then to the injection pump (7). Both of these lines are under positive pressure.

Fuel Sedimenter

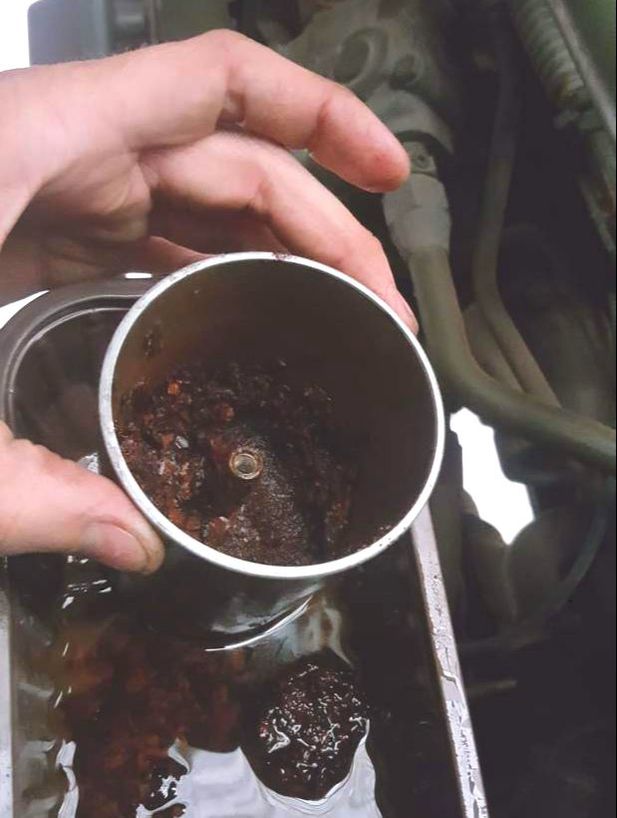

After 10+ years the steel tank is bound to rust and the rust particles will make their way into the sedimenter. Undoing the banjo bolt on the bottom might yield clear diesel but that doesn't mean the sedimenter is not full of rust. I found this out the hard way.

|

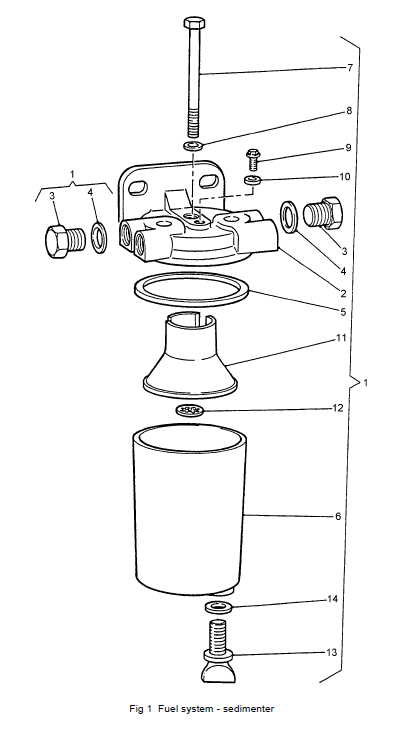

The fuel sedimenter is easily inspected, all that is needed is a 10mm socket or spanner to undo the retaining bolt (7).

Place a "suitable container" (e.g. a food tray from mushrooms) underneath and drain out the diesel by undoing the wing nut (13) underneath. Undo the bolt (7) and hold the canister (6) as you do. The bolt is very long and it might take a while to undo. Once it's off remove the canister and have a look inside. Check the seals in bold below for cracks that could let in air. 1. Bolt/washer assembly 2. Sedminter body 3. Plug 4. Washer 5. Seal [Nato #: 5330-99-316-3303] 6. Bowl 7. Bolt (machine) 8. Flat washer 9. Screw 10. Gasket 11. Sedimenter cone 12.Lock washer 13. Screwed plug (M10 x 1.5) 14. Flat washer [Nato #: 5310-99-513-7047] |

What I found

In my case the sedimenter was so full of rust that it was impeding fuel flow. If you buy one of these and haven't replaced the fuel tank and line, it's advisable to check the sedminter regularly.

At the same time, I also replaced the fuel filter as, with that much rust in the sedimenter it's guaranteed that the fuel filter is clogged. I will be replacing the smaller 135 litre tank with a larger 168 litre or 200 litre tank and when I do, I'll change the fuel lines to rubber hoses to avoid the awful push-fit connections. 168 litres + 2 jerry cans should give a 600 mile range, which is more than enough for us.

Symptoms of a dry fuel system

One way to check is to pump the manual lever on the fuel lift pump a few times. If you can't feel any resistance then the fuel line is probably full of air. Make sure the lift pump isn't sitting on the cam by flicking the ignition slightly to turn the engine. If there is still no To double check, unscrew the wing bolt on the bottom of the fuel sedimenter (4 on the diagram below). This can be found at the back (south) end of the engine. Hold a small container under this and unscrew a few turns, if no fuel comes out, then you're out of fuel.

What to do if you run out of fuel (completely) and your fuel system is dry

- Fill up with fuel (obviously). I filled up with 2 jerry cans so 40 litres total.

- The entire supply line is dry so the lift pump isn't going to help you. The solution is to (gently) pressurise the fuel tank. I used an electric air compressor for an inflatable bed, put some foam around the face of it so that it made a tight seal with the fuel filler neck. My better half then held the air compressor to the filler neck.

- Open the wing bolt on the bottom of the sedimenter while holding a container underneath. When you pressurise the fuel tank, diesel should start to flow out confirming that the tank is pressurised enough. Stop pressurising and do the wing bolt back up and try not to get diesel everywhere.

- Loosen the banjo bolt where the lift pump connects to the sedimenter. Put rags underneath the banjo bolt to absorb the diesel that will leak. I cut the top off a bottle and placed that underneath the banjo bolt, then i used a piece of angle iron to channel the diesel down to a larger container. Pump the fuel lift pump until you start to feel resistance. Once you can feel that it's pumping diesel and not just air, you can stop pressurising the tank.

- Keep bleeding the fuel system until no more bubbles come out of the banjo bolt. I kept going until about 2 litres had been bled through (100+ presses of the fuel lift pump lever). Do the banjo bolt back up and return the diesel to the fuel tank.

- It might be a good idea to make sure the fuel filter is full too, but I didn't.

- At this point I started the truck. You can do this with the cab lifted if you carefully open the drivers door all the way. The manual states that you should start with the accelerator fully depressed so use your left hand to do this and right hand on the ignition. The manual states that you should crank for a maximum of 30 seconds, and wait 2 minutes between tries for the batteries to recover.

- Ours still had a fair bit of air in the system and it was a rough start. Once it started it took a while to idle properly, and then was a low idle. The engine wouldn't rev past 1300rpm and at that point white smoke poured out of the exhaust. After 10 minutes however, the idle suddenly picked up and the truck would rev as normal.